During the cycling process, bicycle handlebar tape has a crucial impact on the cycling experience. Regularly replacing bicycle handlebar tape can not only enhance the comfort of cycling but also improve controllability and anti-slip, safeguarding both safety and enjoyment during rides.

Relieving Hand Fatigue: Comfortable Bicycle Handlebar Tape.

When cycling, hands hold the handlebars for a long time. As the usage time increases, the handlebar tape gradually wears out, deforms, and loses its original elasticity. Old tape becomes stiff and is unable to effectively buffer the vibrations generated during cycling. As a result, the hands directly bear the impact from the road surface, making the hand muscles prone to fatigue, soreness, and even possibly leading to hand joint injuries. In contrast, new handlebar tape usually has good elasticity and softness. It can better conform to the curves of the hands, distribute hand pressure, and keep the hands in a comfortable state throughout the ride. During long - distance cycling, cyclists using new tape will experience significantly less hand fatigue, enabling them to complete their cycling journeys more easily and enjoy the fun of cycling.

Ensuring Cycling Safety: Stable and Safe Bicycle Handlebar Tape.

The controllability of bicycle handlebar tape is directly related to cycling safety. The surface of old tape may show signs of wear, fraying, etc., which can affect the friction between the hands and the handlebars and reduce the ability to control the handlebars. Regularly replacing the tape ensures that the handlebar surface always maintains good friction. New bicycle handlebar tape usually has appropriate textures and materials that can increase the friction between the hands and the handlebars, making it easier for cyclists to grip the handlebars. Whether riding at high speeds on flat roads or winding through rugged mountain paths, cyclists can control the direction and speed of their bicycles more precisely, thus improving cycling safety. Good bicycle handlebar tape controllability allows cyclists to face various challenges more calmly and avoid falling due to hand slippage.

Coping with Adverse Weather: Anti-slip Bicycle Handlebar Tape.

During cycling, it is inevitable to encounter adverse weather conditions such as rainy or snowy days. In these situations, the road surface is slippery, and hands are also prone to sweating. If the tape has poor slip-resistance, the hands can easily slip off the handlebars, causing the cycling to get out of control. Due to long-term use, the slip-resistance of old tape significantly decreases, and it is even more difficult to provide sufficient slip-resistance in adverse weather. New bicycle handlebar tape adopts special materials and textures to increase the friction between the hands and the handlebars. Even when cycling in the rain with water stains on the hands or when the hands are sweaty, new tape can provide reliable slip-resistance, allowing cyclists to hold the handlebars steadily and reduce the risk of accidents caused by hand slippage.

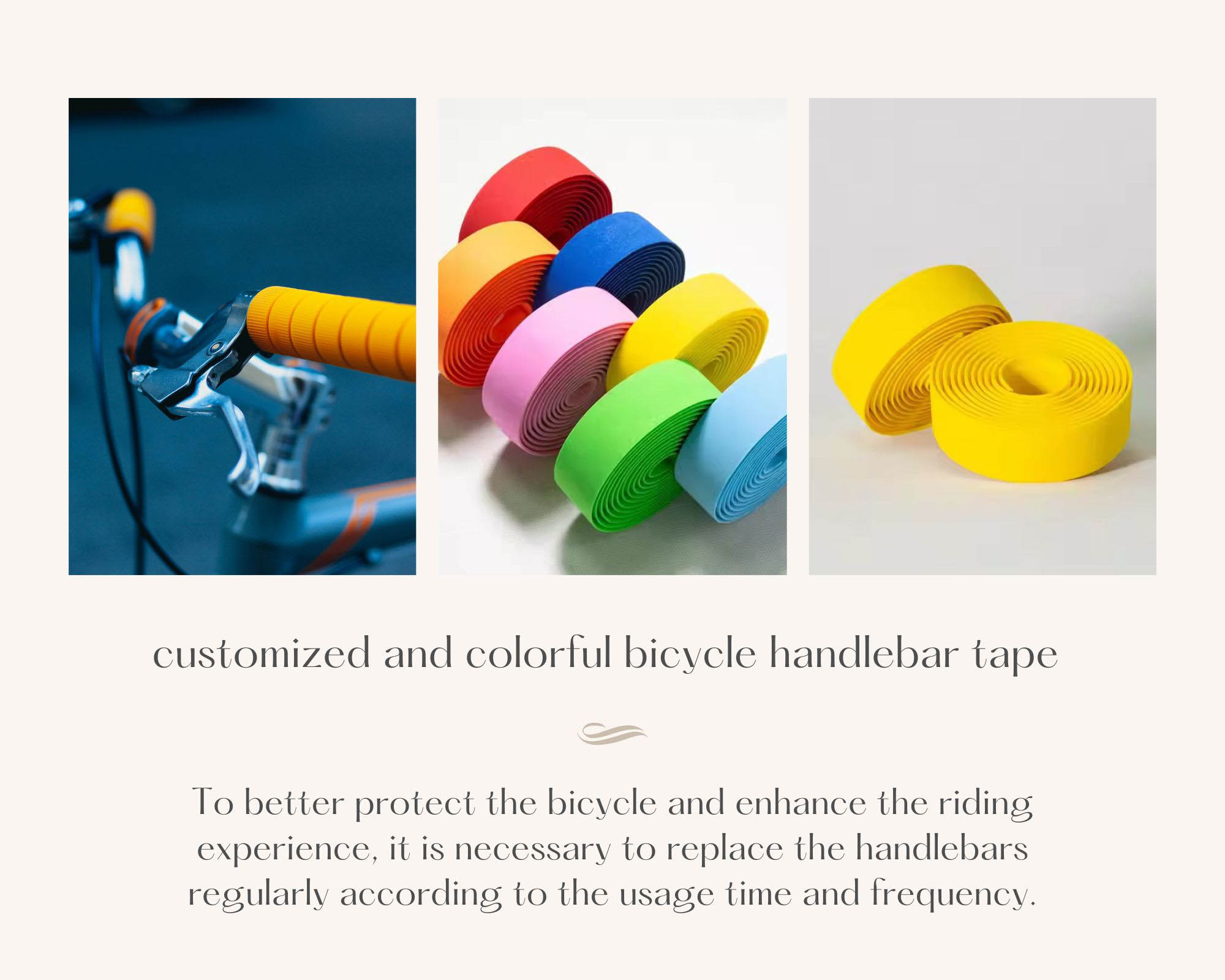

Enhancing Cycling Mood: Customized and Colorful Bicycle Handlebar Tape.

In addition to the above-mentioned functional impacts, regularly replacing bicycle handlebar tape can also keep the bicycle looking neat and beautiful. After long-term use, old tape becomes dirty and shabby, affecting the overall appearance of the bicycle. However, new bicycle handlebar tape with bright colors and good texture can add a new vitality to the bicycle.

Regularly replacing bicycle handlebar tape is of great importance for cycling. It not only enhances cycling comfort, relieves hand fatigue, improves controllability and anti-slip, and ensures cycling safety but also keeps the bicycle looking neat and beautiful, enhancing the cycling mood. Therefore, it is recommended that cyclists regularly check and replace their bicycle handlebar tape according to their cycling frequency and usage conditions, adding more guarantees and fun to their cycling journeys.